- Titanium reactor

- Titanium composite reactor

- Titanium heat exchanger

- Titanium evaporator

- Flue gas heat exchanger

- Air flue gas heat exchanger

- Whitening heat exchanger

- Gas heat exchanger

- Air cooler

- Air coolers

- Compressed air pretreatment device

- Hot air without power recovery device

- Air dehumidification, water distribution device

- Energy saving (waste heat recovery) alcohol recovery tower

- QF gas-liquid separator

Air flue gas heat exchanger

Position:Home > PRUDUCT > Air flue gas heat exchanger

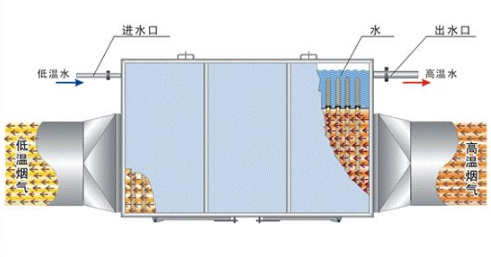

The air flue gas heat exchanger, also known as the flue gas cooler, the flue gas waste heat recovery device, actually converts the heat of the waste flue gas into hot water, hot air, or heat recovery of the waste heat recovery of the hot fluid. device. The air flue gas heat exchanger utilizes the heat of the high temperature or medium temperature flue gas generated by the industrial furnace, boiler, coking furnace, blast furnace, metallurgical furnace, heat exchange through the heat exchanger, recovers heat, and heats water or air. The generated hot water, steam or high-temperature air meets the daily use of hot water, heating, steam for steam generation or food, and material drying.

The residual heat of flue gas utilizes the secondary absorption of flue gas residual heat by the heat exchanger to improve the utilization efficiency of waste heat, which is of great significance for improving the operating efficiency of the boiler. In addition, the waste heat of the flue gas can be significantly enhanced by the use of a heat exchanger in combination with the dust removal device, which helps to reduce the emission of flue gas pollution. Flue gas waste heat utilization of heat exchangers in the boiler system can effectively save energy, reduce smoke pollution emissions, effectively promote China's boiler industry "energy saving and emission reduction", practice green low-carbon cities, "beautiful China."