- Titanium reactor

- Titanium composite reactor

- Titanium heat exchanger

- Titanium evaporator

- Flue gas heat exchanger

- Air flue gas heat exchanger

- Whitening heat exchanger

- Gas heat exchanger

- Air cooler

- Air coolers

- Compressed air pretreatment device

- Hot air without power recovery device

- Air dehumidification, water distribution device

- Energy saving (waste heat recovery) alcohol recovery tower

- QF gas-liquid separator

QF gas-liquid separator

Position:Home > PRUDUCT > QF gas-liquid separator

QF gas-liquid separator

1、 Working principle and characteristics of the equipment

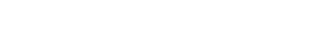

1. Working principle (as shown in Figure 1):

The fermentation (entrained liquid) vapor enters the shell of the gas-liquid separator from the inlet of a; The cavity at the upper part of the inlet is designed to accommodate a large amount of steam in a short time. Under the guidance of the tangent inlet, the steam body rotates from top to bottom along the inner wall of the shell, and the fermentation liquid is separated to the inner wall. Under the action of gravity, the steam body flows back into the fermentation tank through the reflux port b along the cone. The gas part moves upward from the lower end of the inner cylinder under the pressure and is discharged through the exhaust port c (leaving the fermentation tank).

1. Working principle (as shown in Figure 1):

The fermentation (entrained liquid) vapor enters the shell of the gas-liquid separator from the inlet of a; The cavity at the upper part of the inlet is designed to accommodate a large amount of steam in a short time. Under the guidance of the tangent inlet, the steam body rotates from top to bottom along the inner wall of the shell, and the fermentation liquid is separated to the inner wall. Under the action of gravity, the steam body flows back into the fermentation tank through the reflux port b along the cone. The gas part moves upward from the lower end of the inner cylinder under the pressure and is discharged through the exhaust port c (leaving the fermentation tank).

2. Advantages of GQF gas-liquid separator:

GQF gas-liquid separator is an improved new product of our company in the past two years, with the main advantages as follows:

(1) The structure of gas-liquid separator is optimized; Make the upper part of the inner cylinder relatively small to increase the space between the inner cylinder and the outer cylinder, so as to meet the working condition that the fermentation tank (short term) will produce a lot of bubbles and still have good gas-liquid separation effect.

(2) The middle and lower passages of the inner cylinder and the outer cylinder are properly reduced, which can increase the flow rate of steam in the passage and improve the gas-liquid separation effect.

(3) Properly extend the length of the inner cylinder (compared with the old unit) to increase the gas-liquid separation effect.

(4) The improved separator has removed the original "return pipe, internal resistance baffle" and other components, which can reduce the phenomenon of material accumulation and residue in the equipment, and can eliminate the probability of bacteria contamination in the equipment itself.

(5) The upper part of the inner cylinder is designed in the form of head to ensure no material accumulation; There is no "dead corner and overlap" inside the barrel to ensure that there is no residual phenomenon inside the equipment.

(6) The inside of the separator (all material contact parts) is "mirror finish polishing" to ensure that there is no residue in the cylinder.

(7) Since the improved separator has simple structure and "no dead angle, no blocking plate" inside, it can completely complete the disinfection (sterilization) of the separator without residue while the fermentation tank is disinfected as a whole.

2、 Installation requirements, use, disinfection and other requirements

1. As shown in Figure 2; Install the gas-liquid separator on the top of the fermentation tank and connect it with various pipe orifices, pipes and valves marked on the drawing.

2. All flange gaskets of gas-liquid separator are made of tetrafluoroethylene.

3. A valve must be installed behind the gas outlet of the gas-liquid separator (installed by the user separately), and the height of the valve must be lower than the height of the gas outlet of the separator.

4. The depth of the gas-liquid separator return pipe inserted into the fermentation tank is greater than 1/2 of the tank length.

5. When sterilizing the fermentation tank, the vent valve of the gas-liquid separator must be closed until the sterilization process is completed.

6. The device is designed according to the physical principle and has no moving parts, so it has no vulnerable parts.

GQF gas-liquid separator is an improved new product of our company in the past two years, with the main advantages as follows:

(1) The structure of gas-liquid separator is optimized; Make the upper part of the inner cylinder relatively small to increase the space between the inner cylinder and the outer cylinder, so as to meet the working condition that the fermentation tank (short term) will produce a lot of bubbles and still have good gas-liquid separation effect.

(2) The middle and lower passages of the inner cylinder and the outer cylinder are properly reduced, which can increase the flow rate of steam in the passage and improve the gas-liquid separation effect.

(3) Properly extend the length of the inner cylinder (compared with the old unit) to increase the gas-liquid separation effect.

(4) The improved separator has removed the original "return pipe, internal resistance baffle" and other components, which can reduce the phenomenon of material accumulation and residue in the equipment, and can eliminate the probability of bacteria contamination in the equipment itself.

(5) The upper part of the inner cylinder is designed in the form of head to ensure no material accumulation; There is no "dead corner and overlap" inside the barrel to ensure that there is no residual phenomenon inside the equipment.

(6) The inside of the separator (all material contact parts) is "mirror finish polishing" to ensure that there is no residue in the cylinder.

(7) Since the improved separator has simple structure and "no dead angle, no blocking plate" inside, it can completely complete the disinfection (sterilization) of the separator without residue while the fermentation tank is disinfected as a whole.

2、 Installation requirements, use, disinfection and other requirements

1. As shown in Figure 2; Install the gas-liquid separator on the top of the fermentation tank and connect it with various pipe orifices, pipes and valves marked on the drawing.

2. All flange gaskets of gas-liquid separator are made of tetrafluoroethylene.

3. A valve must be installed behind the gas outlet of the gas-liquid separator (installed by the user separately), and the height of the valve must be lower than the height of the gas outlet of the separator.

4. The depth of the gas-liquid separator return pipe inserted into the fermentation tank is greater than 1/2 of the tank length.

5. When sterilizing the fermentation tank, the vent valve of the gas-liquid separator must be closed until the sterilization process is completed.

6. The device is designed according to the physical principle and has no moving parts, so it has no vulnerable parts.

PRE:None

NEXT:Air cooler

Related products